Table of Contents

Understanding Reactive Power Compensation Controllers

Solutions in Reactive Power Compensation Controllers

-

Capacitor Compensation: Uses capacitors for lead reactive power, which solves inductive loads’ reactive power issues, improves power factor, and reduces reactive power demand.

-

Inductor Compensation: Employs inductors to supply lagging reactive power while balancing leading reactive power engendered by capacitive loads.

-

Synchronous Generator Compensation: Involves synchronous generators in over-excited mode to deliver reactive power, which aids in voltage control and stability.

-

Static Var Compensator (SVC): A fast-acting, thyristor-controlled system that switches between capacitive and inductive modes to adjust reactive power flow and voltage stability.

-

Static Synchronous Compensator (STATCOM): Uses voltage source converters to inject reactive power into the system for better dynamic response and voltage control over SVC.

Benefits of Capacitor Compensation

Key Factors in Choosing a Capacitor for Compensation

1. Voltage Rating

In picking capacitors for a compensation controller, voltage rating is key. It must surpass the maximum system voltage, including transients, to avert dielectric breakdown. For instance, in a 400V system, a capacitor with a minimum rating of 450V might be good. It ensures reliability in applications with unsettled voltages or surges. Furthermore, considering voltage derating – using a capacitor at a lower voltage than its maximum rating – augments performance stability and life.

2. Capacitance Value

The capacitance value helps tune the performance of a compensation controller. It influences the reactive power provided and requires precision in selection. E.g., higher capacitance is needed in systems with reactive power demand, including heavy motor startups. Choosing the correct value gives efficient power factor correction and curtails energy losses. It balances the capacitance to circumvent overcompensation, which can cause a leading power factor and resonance issues.

3. Size and Physical Dimensions

The size of the capacitors is critical in system design for a compensation controller. Compact, high-capacity capacitors are better in space-constrained environments. Yet, larger capacitors might be for high-power uses owing to their higher energy density. For instance, picking capacitors that balance size and power handling capability is necessary in industrial settings with premium space and increased power demand. It gives the best design without negotiating performance.

4. Type of Capacitors

Knowing different types of capacitors is important for a compensation controller. LV capacitors with self-healing offer reliability and can self-repair minor dielectric breakdowns. Dry capacitors are free from liquid dielectrics and are safer and eco-friendly for indoor applications. Conversely, oil-immersed capacitors shine in high-power applications with thermal conductivity and cooling efficiency. Choosing between dry-type and oil-immersed capacitors centers on thermal management and environmental considerations. Each type has discrete advantages (like the better heat dissipation of oil-immersed capacitors), which is beneficial in high-temperature settings.

Concerns of Reactive Power Compensation Scheme Configuration

- Relationship with User System Capacity: Increasing system capacity necessitates heightened reactive power support; larger loads require more reactive power management. Consequently, a well-designed reactive power compensation scheme scales with the system size while using capacitor banks and synchronous condensers for management.

- Relationship with the Quantity of Transformer Containers: Higher numbers of transformer containers imply greater complexity in reactive power flows. It demands refined coordination. Additionally, it requires unconventional compensation controllers that adjust to erratic transformer loads for efficient reactive power distribution.

- Design Considerations for New Systems with Reactive Power Compensation: Integrating adaptive compensation technologies, including STATCOM or SVC, early for new systems can proactively address reactive power imbalances. Also, initial designs should consider future scalability for surplus compensation units as load demands change.

- Design Considerations for Maintenance and Replacement: Systematic maintenance of compensation equipment, including capacitor banks and reactors, thwarts system inefficiencies or failures. Likewise, when replacing components, evaluate newer technologies such as solid-state capacitors or digital compensation controllers.

Conclusion

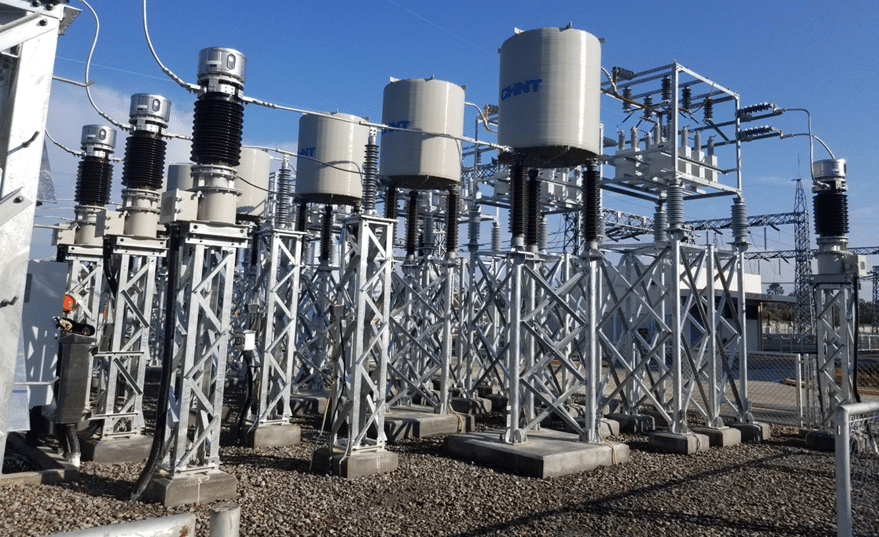

Reactive power compensation controllers are pivotal for maintaining voltage stability and power quality in electrical systems. They can ensure efficient reactive power flow, leading to reduced losses and enhanced stability, particularly crucial in dynamic environments with fluctuating loads and renewable energy sources.

In selecting capacitors for compensation, factors like voltage rating, capacitance value, and type are critical considerations. CHINT offers reliable capacitor solutions, such as the NWC5 and BZMJ series, which exemplify advanced technology and adherence to international standards. By understanding and implementing these solutions effectively, industries can optimize power efficiency, minimize losses, and ensure the robust performance of electrical systems in various applications.