Table of Contents |

Most modern electrical and electronic devices are engineered based on optimizing power, functions, and size. Therefore, power efficiency is among the primary things considered by design engineers. This is particularly true for portable electronics running on batteries such as cameras, tablets, smartphones, various industrial devices, and laptops.

Although most electronic components have been designed for extremely high-power efficiency, they still use power on standby or in “sleep mode .” When this happens, you’d like the device to have a load switch to automatically turn off the supply rail to conserve power and later turn it on whenever your device wakes up.

The switch might also cut off your device from the power supply, protecting it from any damage whenever there are abnormal power situations like an electrical transient, power surge, removal, or insertion of a battery.

What is a Load Switch?

This electronic component does not have any moving parts and works somehow like a relay. In general, two MOSFET transistors act like a switching element, one being a P-channel device and the other one being an N-channel device.

What Is A Load Switch IC?

The load switch IC (Integrated Circuit ) is a power supply IC with inbuilt output drivers and output transistors made using CMOS technologies. This system is significantly smaller than the traditional discrete configuration.

It also has a low-voltage operation, a low current consumption, low-on-resistance characteristics, and a variety of other extra functionalities. The ultra-small items in the one square millimeter class form the focus of the package lineup. The packaging line, in particular, includes products that are ideal for usage in space-constrained portable devices.

What Is A Load Break Switch?

An LBS (Load Break Switch) refers to a disconnect switch designed to break or make the currents specified. You accomplish this by adding a piece of equipment that raises the disconnect switch blade’s operating speed and another kind of equipment that alters the arcing phenomenon while allowing safe interruption of the resulting arc whenever the load currents are switched.

To ensure a restricted load switching capability, the disconnect switches may be supplied together with the equipment. The switches are used for energizing or de-energizing a circuit having a limited amount of capacitive or magnetic current, for instance, line charging current a transformer exiting current.

To add a series interrupter, an air switch (normally SF6 or a vacuum) may be modified. This ensures higher current and voltage interrupting levels. In addition, the interrupters raise the load break capacity of that disconnect switch and might be used for switching the fault or load currents of the equipment.

What Are The Advantages Of Load Break Switch?

Cheaper As Compared To 2 Pole Structure

Regardless of the technology used in a load break switch, its installation and acquisition cost is far lower than a 2-pole structure. However, its price depends on the power source, IP rating, voltage/power, frequency, and current rating. The LBS’s convenient use and reasonable prices make it widely used in distribution network systems of about 10kV.

Safer

A load break switch is mainly used to close and break the load current and can be used with a high-voltage fuse instead of a circuit breaker. The reasonable selection of load balancing switch in the design dramatically helps ensure safety and reliability. As a result, the dangers associated with tripping circuit breakers are eliminated, providing a safer power grid operation.

Provided With Fuse Protection

Load break switches also feature HRC fuses for transformer protection, ensuring more safety and reliable operation. However, you also can use a vacuum circuit breaker, although it is a bit costlier and more reliable.

In addition, the transmission lines are protected from overheating, leading to fires, while the appliances like transformers are protected from the damages that might be caused by short-circuiting or catching fires.

Turning The Power Supply On & Off Is Easy

Load break switches usually feature a spring mechanism for switching the power supply on or off. This makes the process of turning the power supply on or off easier.

Difference Between Load Break Switch and Isolating Switch?

Isolating Switches

Also called a disconnector, an isolating switch is a mechanical device that fulfills the specified requirements for IEC 60947-1 (isolation function). Here, the critical factor is the opening distance. The isolation should be guaranteed between poles and from output to input. This is by means of an isolation gap that is visible or some design features inside the device.

The device should also feature an indicator device that shows the position of the movable contacts that must be securely linked to the actuator. According to IEC 60947-3, the isolator should only break and make a circuit if a negligibly sized current is switched off or on, or if there isn’t any noticeable difference of voltages between terminals of each pole.

It can conduct operational currents in normal conditions and larger currents under abnormal conditions for a specific time. The requirements under IEC 60947-3 can be achieved through fuse connectors, disconnectors, switch disconnectors, and circuit breakers having isolating functions.

Load Break Switches

The LBS are mechanical switching devices that can make, break, and carry currents under normal circuitry conditions. This might include a particular overload condition and carrying currents for a specific amount of time under specific abnormal conditions in the circuit, for instance, during short-circuiting.

Although a load break switch might have the short-circuit making capacity, it lacks the breaking capacity specified under IEC 60947-1. This means that the shirt circuit current may be conducted but not switched off. A load transfer switch is an electrical component that will then switch that load between two sources.

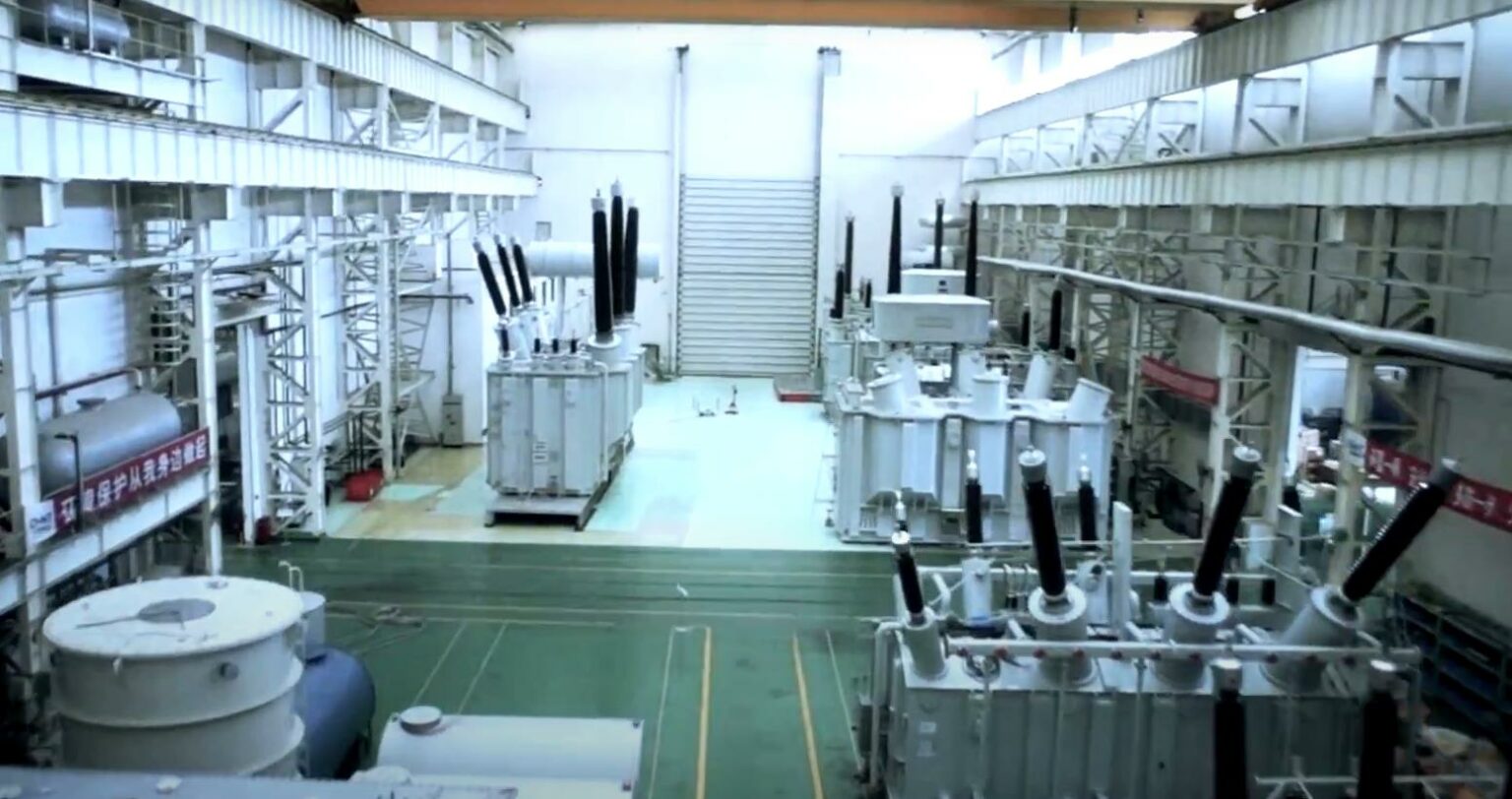

The CHINT Load Break Switch

So, where can you get quality load break switches at a pocket-friendly price? There is only one place, CHINT. This is a globally renowned producer of high-quality electrical and electronic equipment, including Load Break Switches (LBS). The CHINT load break switches boast many features, including flexible installation, high breaking capacity, automation distribution interface, lightweight, and compact design.

By purchasing a load break from CHINT, you are sure that you get a quality electrical component that is maintenance-free. Regardless of your power system, you can choose from various models with different standards like NFZ77 and FLN36 IEC 62271-105, IEC 60265-1, among others. These load break switches are used for breaking and making short circuit breaking current between 12-25kV AC50Hz load currents.

Conclusion

Power transmission out to be reliable and safe. One of the vital electrical parts that ensure a Load breaking switch. They have many advantages, including safety, ease of turning off and on, and are relatively cheaper than 2-pole structures. Being global renown for producing these electrical appliances, ensure you rely on CHINT for all your LBS needs. Head on to our website and select one based on your power need.