Table of Contents |

AC contactors have a crucial role in electrical circuit systems. It helps in the effective control and management of electricity flow across various high-current demanding loads. It is widely used in operating HVAC, compressors, heavy-duty motors, and similar others. This guide discusses in detail about what an AC contactor is, its components, functions, and the key factors to consider when purchasing it.

What is an AC Contactor?

An AC contactor is an electromechanical switching device designed to switch AC loads on/off. It is used for switching high-current AC loads.

The working principle of the AC contactor involves electromagnetic force cooperating with the spring force to make and break the connection between the source and load. Basically, when the coil is energized with a low voltage, it generates a magnetic field and attracts the armature. This causes the movement of the contacts and makes the circuit complete.

Components of an AC Contactor

There are three main components of an AC contactor:

1. Coil or Electromagnet

The coil or electromagnet acts as a control switch. It is wound with a number of turns of insulated wire and can be energized by AC voltage or DC voltage.

2. Contact

The contact plays the role of connecting and interrupting the main circuit. There are mostly two types of contacts, i.e., main contacts and auxiliary contacts. The main contacts consist of static and moving contacts.

Auxiliary contacts are additional sets of contacts present in some AC contactors. They are used for interlocking between devices and signaling control.

3. Enclosure

Enclosure is the covering that provides insulation and protection to the coil and contacts. It is mostly made of non-conductive materials and comes with features like protective covers, terminals, and mounting brackets.

Functions of an AC Contactor

An AC contactor offers a wide range of functions in various commercial and industrial applications. Its primary function is to switch heavy electrical loads by energizing and de-energizing the coils. The key functions are as follows:

- Controlling high-powered lighting systems

- Facilitating automation systems

- Controlling multiple loads in an industrial setup

- Switching power in industrial equipment

- Protecting circuits from overloading and short circuits

In short, AC contactors are widely used thanks to a wide range of functionalities for managing higher-power applications.

Key Factors to Consider when Selection an AC Contactor

Considering the widespread use of AC contactors, there are now different varieties of AC contactors available today. This makes it overwhelming to choose the best one that matches your needs.

To help ease this hassle, we have shortlisted a few key factors to consider when selecting an AC contactor below:

1. Voltage Rating

The voltage rating of the AC contactor should be equal to the maximum voltage of the system it will operate in.

2. Current Rating

The current rating should be higher than the system it will operate in. It should be able to handle the load current along with the initial inrush current during the start of the system.

3. Number of Poles

AC contactors are mostly available in 3-pole and 4-pole versions. You can choose between them depending on the load type and control circuit requirements. For instance, 3-pole AC contactors are usable in three-phase systems, while 4-pole AC contactors can be used in 3 phase 4 wire system or 1 phase 2 wire system.

4. Lifespan

Make sure the product you use should have a prolonged lifespan. For that, you should consider the contactor’s mechanical and electrical life. The mechanical life refers to the number of switching cycles before wear affects performance. Similarly, electrical life refers to the number of operations under load. You should pick the contactor rated for millions of cycles.

5. Size and Mounting

You should evaluate the location in the control panel where you want to place the AC contactor. Afterward, pick the AC contactor whose size and mounting match your requirements.

6. Price and Budget

A high-quality AC contactor can be expensive but offers longer reliability. The recommended approach is to research the products of different manufacturers for your specific ratings and then pick the ones that are aligned with your budget.

7. Certifications

Make sure the AC contactor holds credible certifications. CE and UL are some important certifications to consider. You can find such information on the manufacturer’s product page.

Conclusion

AC contactors are necessary control systems to regulate the flow of electricity in heavy electrical loads. That’s why they are used in wide applications, ranging from electric motor starters to managing multiple electrical loads in industrial setups. Therefore, consider the above key factors and find the best quality AC contactors for your needs.

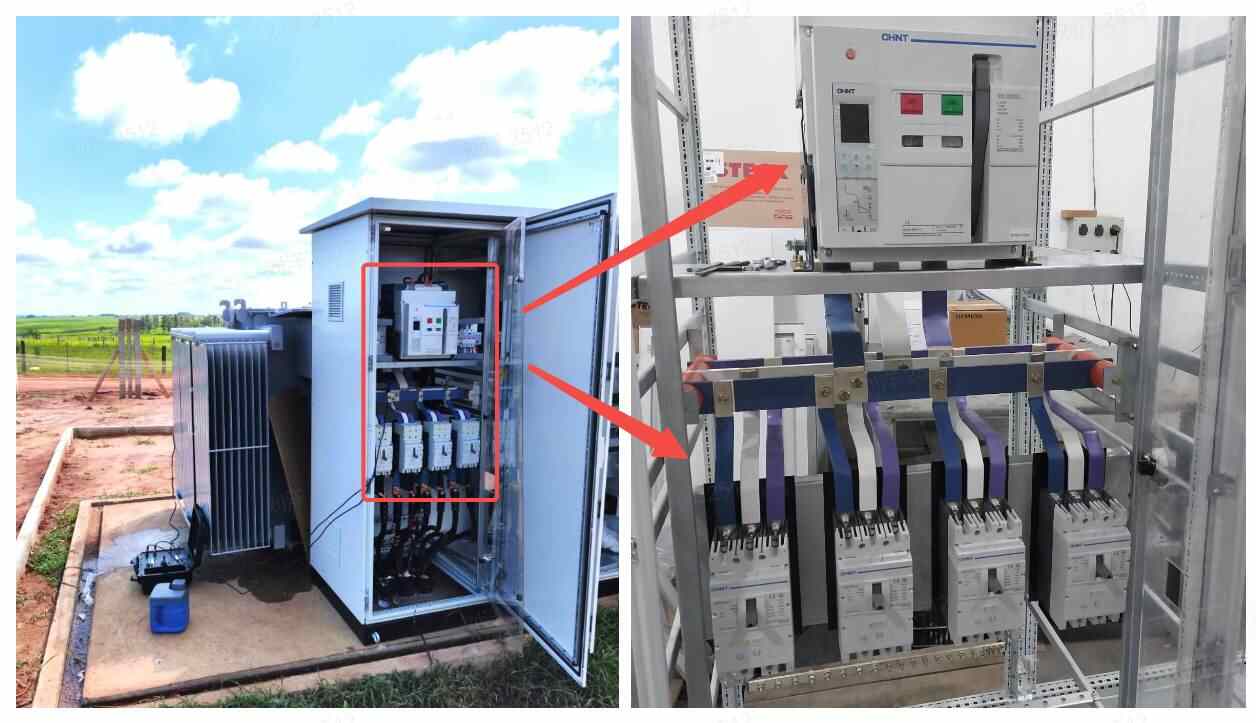

Alternatively, you can simply opt for CHINT contactors, as the company is reputed to offer premium quality and a wide range of contactors for different applications. CHINT’s NC6 AC Contactor (6~9A) comes with an electric rating of AC 50/60Hz and up to 690V. It also holds EAC, UL, VDE, CE, and other certifications. NC8 AC Contactor (6-2650A) and NXC AC Contactor (6-630A) come with a similar rated operational voltage and frequency but offer a higher rated operational current, which ensure reliable operation across various applications. Visit CHINT’s website for more information about NC6 AC Contactor and the rich product line of CHINT.