Table of Contents

An electrical laboratory is an important facility that allows electrical equipment and components to undergo extensive testing. This helps ensure the safety, reliability, and performance of electrical solutions before being introduced to the market. At CHINT, we have an advanced intelligent electrical laboratory center that takes experimental testing to the next level. Known as CHINT Intelligent Electrical Laboratory Center, it is more than just a place for testing. It’s a comprehensive experimental platform that seamlessly brings together R&D process experiments, multi-standard product testing, smart manufacturing, and field application simulations. This gives us the ability to provide high-quality R&D support, quick project execution, and fully customized solutions that meet global customer needs from start to finish.

CHINT Intelligent Electrical Laboratory Center: A Comprehensive Experimental Platform

CHINT Intelligent Electrical Laboratory Center is a best-in-class experimental facility. As a comprehensive platform, it allows for testing in real-world conditions and scenarios. This improves research capabilities and helps speed up solution development. Some of its key highlights include:

1. 24/7 Power Supply Systems

The various backup systems, like the 350MVA generator, ensure uninterrupted power for experiments day or night. This generator is an important asset, capable of simultaneously outputting both 50Hz and 60Hz frequencies through adjustable speed control. It can generate up to 350 megavolt-amperes of power, far exceeding normal testing needs. Additional systems include a 1,600kVA generator set and dedicated 35kV power lines to ensure redundancy.

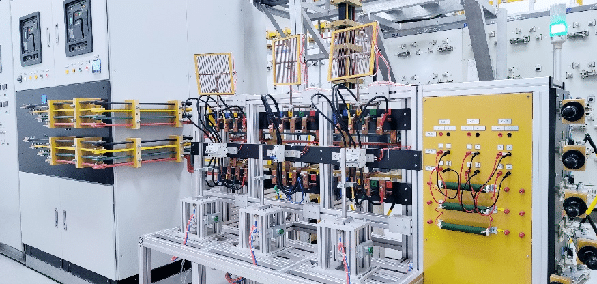

2. Various Testing Equipment

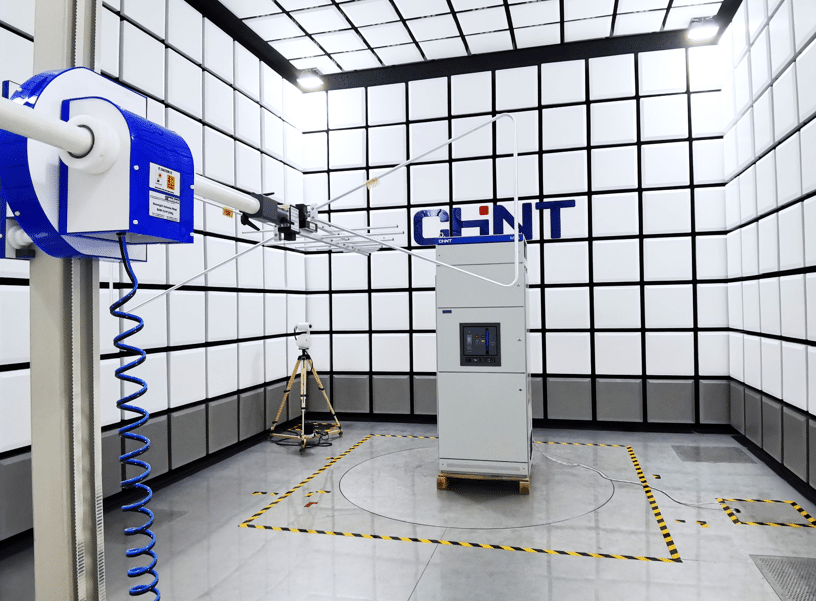

A wide array of state-of-the-art tools are available, like the flagship 150kA short circuit test system and advanced EMC lab equipped with a large anechoic chamber. The EMC lab stands out with its ability to simulation test components directly as well as complete cabinets. Its testing frequency and field strengths far surpass standards, allowing for more robust evaluation.

3. Central Control System

Tests can be actively monitored and controlled through the centralized platform. It integrates monitoring of power infrastructure, experiment management systems, and several high-definition cameras for safety oversight. Researchers can even witness live experiments through integrated video connections and data visualization tools.

Comprehensive Test Items of the Center

The CHINT Intelligent Electrical Laboratory Center provides the means to conduct thorough assessments of all key product aspects. Its array of advanced equipment enables testing across critical factors like short circuit behavior, EMC performance, and operational resilience. As a state-of-the-art facility, it maintains extensive verification abilities to fully check that solutions satisfy high standards. Comprehensive test items include:

Short Circuit Test

Powerful systems like the 350 megavolts amperes experimental equipment power generator and 150kA short circuit generator in the No. 1 Central Control Room simulate extreme faults. The No. 1 Central Control Room can actively control 8 generators rated up to 150kA at 480V or 150kA at 635V. DC can reach 100kV at 1000V. Precise control of current, voltage, and waveform allows a thorough investigation of product response under various short-circuit scenarios.

EMC Electromagnetic Test

Both component-level and cabinet-level EMC experiments can be conducted in the 3-meter anechoic chamber of the EMC electromagnetic laboratory. The test frequency of the RF radiation system is as high as 6Gherz, with a field strength of 30V/m, much higher GB standards. The EMC electromagnetic laboratory enables the conduct of 16 electromagnetic compatibility experiments.

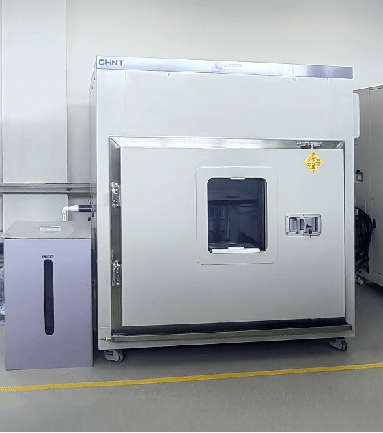

Complete Cabinet Test

The modular Complete Cabinet Experimental Well undergoes exhaustive multi-condition assessments for complete cabinets. Its power input flexibility and overhead crane recreate diverse environments for reliability and durability analysis, such as short circuits, overloading, and prolonged exposure to vibrations, shocks, dust, and humidity. It can handle up to 10-ton heavy load for realistic experiments.

Environmental Reliability Test

Specialized electrical lab sections of the CHINT Intelligent Electrical Laboratory Center deliberately expose products to parameters like extreme temperatures, 85% humidity, salt spray, dust, etc. Monitoring tracks performance changes to verify stability. A rapid temperature change chamber is used for high acceleration life tests. The system application lab is used to simulate actual power usage scenarios and test the stability of product operation or consistency of functions.

Conclusion

Overall, the CHINT Intelligent Electrical Laboratory Center demonstrates an innovative comprehensive experimental approach through its integrated platform. The laboratory’s diverse advanced equipment and digital infrastructure allow for rigorous testing and validation of electrical solutions under both controlled and realistic conditions.At CHINT, we have developed strong R&D expertise that delivers high-quality energy products tailored to global customer needs. With a prominent experimental facility, we are equipped to continue enhancing our portfolio of technologies and solutions for electrical equipment. The electrical lab center exemplifies our commitment to exploration and innovation in the energy sector. To learn more about our testing services and solutions, browse our website.