Table of Contents |

Circuit breakers have been used for decades to prevent power surges and failures due to circuits overloading. Traditionally, they use a fuse that must be replaced after every use. However, air circuit breakers have recently grown in popularity due to their enhanced features and functions.

What is an Air Circuit Breaker?

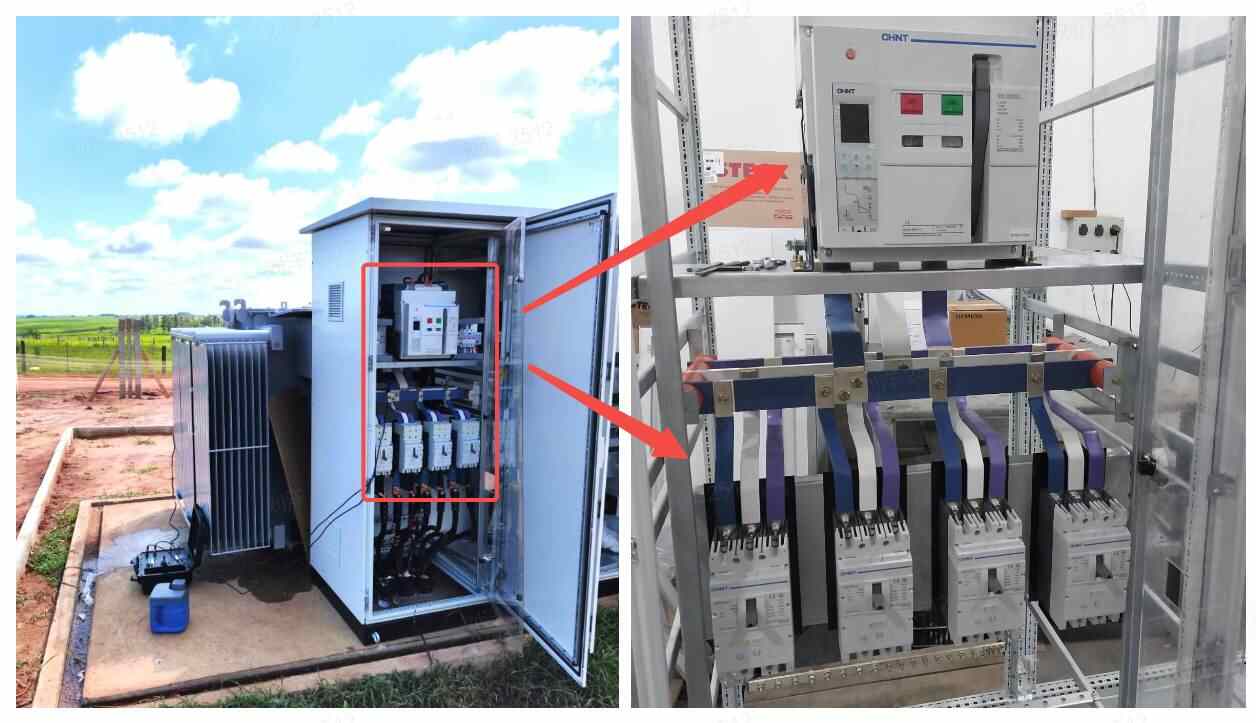

An air circuit breaker is an important safety equipment for any electrical line. It is a switch that operates automatically whenever a power surge or other fault is detected. It is designed to prevent the system from overloading, which can potentially ruin devices plugged into the power source or start a fire.

The circuit breaker was first theorized by Thomas Edison in 1879, although the first model to use air instead of an electrical fuse was not invented until 1949 by the American electrical company Westinghouse. Other models have used oil to break up the electricity as well. They are generally considered by experts to be superior to other forms of circuit breakers.

Features of Air Circuit Breaker

Although there are many different manufacturers and styles, the primary features are generally the same from unit to unit. There are four types of ACBs. But for the purposes of this article, we will be focusing primarily on the Air Blast version.

The frame of an ACB usually refers to the outer shell, which is made of aluminum, chromium steel, or another type of sturdy metal that protects the internal components from dust and other environmental damage. However, it can also refer to the internal insulating frame, which is accompanied by an insulating plate, which houses and protects the contacts.

An ACB will also generally feature two pairs of contacts, although larger industrial units may have more. The first set is usually made of copper and is used to conduct electricity along its normal path during normal operation. The second set is made of carbon and is used as a failsafe to prevent excess electricity from the first pair from being able to do any damage.

An air circuit breaker’s arc chute is a pathway designed to contain the arc and keep its path out of the way of the rest of the internal mechanisms. It uses insulation to perform this task because it does not conduct electricity and can be absorbed harmlessly into the insulating material.

The main operating mechanism is, as the name suggests, the part that allows the unit to function as intended. This part shoots out of the burst of compressed air. It prevents the electrical arc from reforming until the voltage is low enough that the underlying system can handle it without overloading.

Working Principles and Functions

The primary function of an ACB is to prevent an arc of electricity from reforming when its voltage becomes too high for the system to handle. Unlike traditional models that use a fuse or oil, they use bursts of compressed air to disrupt the electrical impulses and keep the voltage entering the system from becoming high enough to be dangerous.

They also prevent an electrical arc from overloading the system after a power surge or another event. This can happen in various ways but the most common is after a power outage. When the city grid is restored and the electricity begins to flow again, it can overwhelm a system that isn’t prepared for it.

ABCs also prevent short circuits, which can cause overheating, electrical fires, or even explosions. These are caused by an imbalance between the voltage of two separate circuits, which makes the current go the wrong way. An ACB will stop the flow of electricity before any of those things can happen.

They also create isolation as another means of protection, which is an electrical term that refers to the act of stopping corrosion. These systems can easily become corroded without proper isolation because of stray currents created by the different types of metal used.

This is one of the major functions of the insulation used in these systems, which absorbs the extra electricity and is not conductive, meaning those electrical charges will disappear harmlessly.

You may be interested in this blogpost

Why You Need an Air Circuit Breaker for Your Equipment

Air Circuit Breakers: Maintenance Tips

Like all machines, an ACB will require proper care to ensure it continues operating at peak performance. One of the best ways to achieve this is by regularly maintaining the unit. Here are a few things to keep in mind for each maintenance period, which should be at regular intervals, a couple of times per year at minimum.

The first thing to do is to check to see that the insulation inside the unit is dry, as wet insulation is not only less effective but is a breeding ground for mold. A handheld vacuum can be used to clean it or a lint-free rag or towel will work. You’ll also want to check all the parts for potential damage.

The next step is to check the contacts to make sure that they have no signs of rust or damage. If you have access to a micro-ohmmeter, you should also check to make sure that the contacts are still functioning properly. Finally, you’ll want to ensure everything has the correct alignment.

Most importantly, the machine should be checked for dryness, except the operating mechanism, which should be properly lubricated.

Conclusion

By understanding the features and functions of an ACB, users will better understand which type will work best for their particular situation. Chint Global Products has sold high-quality air circuit breakers and electrical supplies in general for over 40 years, making them the perfect choice for first-time ACB purchasers.