Table of Contents |

Contactors have auxiliary contacts and main contacts, auxiliary contact is the contact in the auxiliary circuit that is operated mechanically. It is physically linked to the main contacts and activated at the same time. It does not carry so much current. Auxiliary contact is also referred to as supplementary contact or control contact.

What is an auxiliary contact?

An auxiliary contact (or switch) is an additional contact that forms a part of a circuit to increase the amount of electricity that can flow through the system. These are usually installed when there is already some primary source, but too much power needs to pass through for just one auxiliary contact to handle.

At least two contacts are required for this system to operate. When only one auxiliary was present, it would be possible for more current than the entire path could handle to move through one spot on the circuit.

That means that some areas would not get any electricity while others receive far more than they should. With two or more contacts present, it’s possible to limit the amount of electricity that goes through each path, making sure everything is properly powered.

How does auxiliary contactor work?

Typically, the wire to the relay or fuse may burn when an overload trips a relay or fuse. If that happens often, it could cause smoke in your system. An auxiliary contactor allows one switch to control another (usually larger) switch.

The auxiliary contactor has a coil with high-power contacts inside and two sets of low current contacts on either end. The “low voltage” set of contacts is usually labeled as such.

In contrast to the main power contactor coils rated for continuous duty throughout an entire plant, auxiliary contactors have time delay features that prevent arcing and possible damage if the auxiliary contactor opens while the main contractor is still energized.

Why use an auxiliary contactor?

1. They protect your circuit breakers (and equipment) from damage

Since auxiliary contactors release a circuit’s overloads, they ensure that the main breaker or fuse isn’t being worked too hard. That helps protect equipment from damage due to current spikes and heat buildup caused by under-capacity fuses and breakers.

In addition, auxiliary contactors help increase circuit breaker life expectancy. Auxiliary contactors are often equipped with their fuses, so if they are overloaded by an event short-circuit, the auxiliary contactor will blow its fuse without affecting the main circuit breaker.

The auxiliary contactor saves equipment from dangerous situations resulting from under-capacity or constantly tripping circuit breakers.

2. They offer enhanced protection against electrical hazards

Auxiliary contactors ensure that dangerous electrical malfunctions don’t occur because overloads have been released. If an overload isn’t released, it can cause failures in circuits and result in shocks or fire hazards due to overheating components. Auxiliary contactors minimize these risks and allow for a more secure work environment.

3. They minimize electrical failure risks

Auxiliary contactors ensure that there isn’t a high load on the circuit breaker, which minimizes the risk of electrical failures. An overloaded circuit will quickly work to blow its fuses or breakers, and this situation can cause overheating and other malfunctions that result in equipment damage and electrical injuries.

Auxiliary contactors release overloads when they reach a certain level, allowing for optimal performance and life expectancy for an electrical system.

4. They help increase circuit breaker life expectancy

If auxiliary contactors didn’t exist, main circuit breakers would be working harder to handle the extra current needed by under-capacity circuits, which would worsen their heat dissipation capabilities.

In time, this would lead up to the deterioration of the circuit breaker and negatively affect its performance. Auxiliary contactors act as current relief valves that ensure the main circuit breakers aren’t exposed to dangerous overloads, which allows them to operate more securely.

Difference between Auxiliary and Main Contacts in Contactor?

1. Main or Power Contacts in Contactor

The main contact uses an insulating disk that separates the two sets of contacts. To make a connection requires a lot more force since both parts of the device must squeeze together until they connect. That makes them especially useful when there is a need for high amperage and voltage protection on circuit breakers and switches.

Main operating contacts are used to control the operation of motor-operated equipment such as switches, circuit breakers, and contactors. The most common example is an AC contactor with both main and auxiliary contacts.

A spring mechanism between the two sets of contacts holds them apart during normal conditions when power is not applied to the device. When the switch or circuit breaker opens, it releases this spring, causing both contacts to come together and operate the coil to close the device again.

2. Auxiliary Contacts in Contactor

The alarm auxiliary contacts do not require as much pressure to be applied. The two sets of contacts are touching each other due to the metal piece that holds them apart at-rest position.

When there is a problem with the AC contactor’s mechanism or if it detects an overload condition, it causes one set of contacts to separate slightly from the other. That allows for voltage to be passed through the device so that protective measures can be taken, including opening the main contacts or disengaging them completely.

Auxiliary contacts are used to monitor conditions so that if they are not operating properly, the main contacts can be opened before there is a problem with the equipment or circuit breaker.

When the auxiliary contact switch is closed, it causes an increase in heat at the contactor’s operator mechanism due to the resistance created by the current flowing through both sets of contacts. This additional heat indicates something is wrong and will give an electrical worker sufficient warning time before a serious situation develops.

Auxiliary contacts also provide overload protection for motors and hydraulic systems, which can cause pipe or valve damage if pressure exceeds certain levels. They can function as pilot lamps on larger devices such as motor control centers (MCCs) or other types of switchgear.

Conclusion

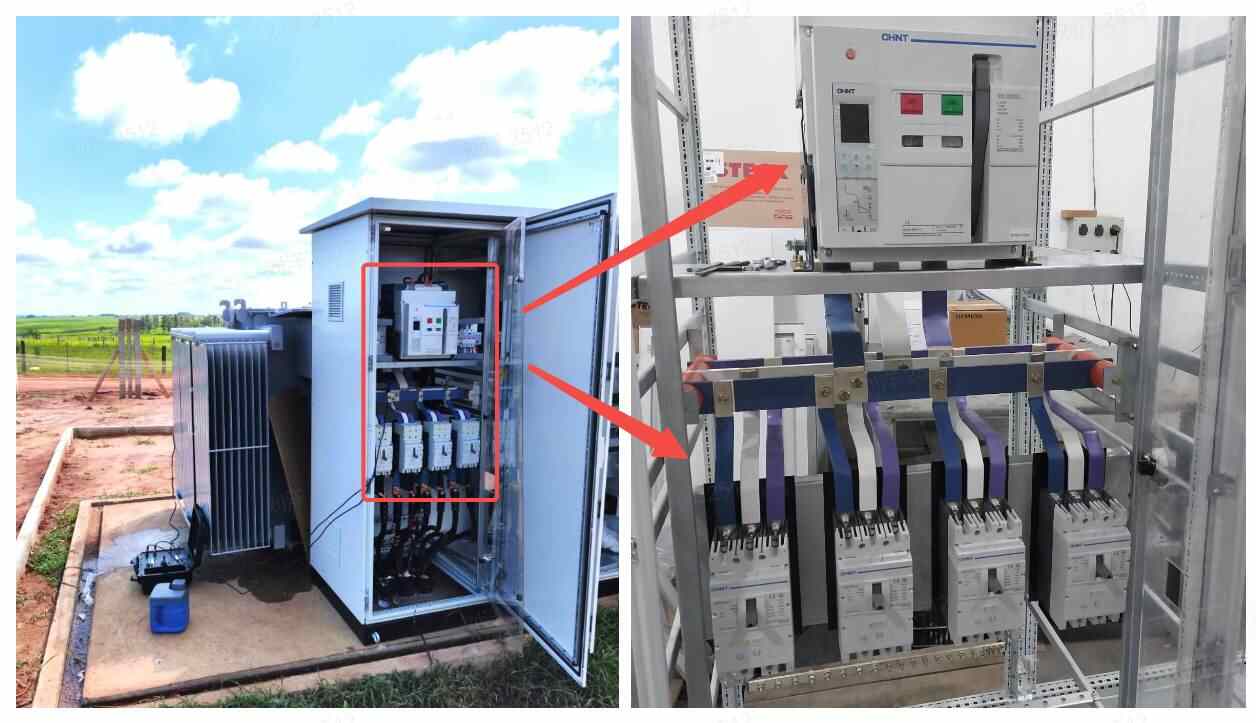

Auxiliary contacts serve several purposes for motor-operated devices and electrical professionals regarding safety and protection against electrical faults. If you need auxiliary contact, CHINT is one of the best companies you should contact since they focus on developing intelligent, reliable, and efficient electrical products.