Table of Contents |

Electrical contactors are components used for automatically controlling current in an electrical circuit. You typically use them in high-voltage circuits to control lighting, heating, electrical motors, and other high-voltage loads.

Some are designed for AC circuits, while others are best for DC loads. Here, we examine the differences between AC and DC contactors to help you choose the right one for your needs.

What Are Contactors?

Contactors are electrical devices that open or close an electrical circuit depending on the application. They work through electromagnetic force around a coil or through AC current to change the position of the contacts. It allows the circuit to be closed and electricity to flow. Once the coil is de-energized, the contacts open, and current is no longer available to the circuit.

You may be also interested in: The Different Types of Contactors and How They Work

Can I Use DC for an AC contactor?

Using a DC contactor in an AC circuit can lead to electrical shorts, equipment damage, and electrical fires. DC contactors typically have a much lower power rating than AC contactors. As a result, the circuit can become overloaded and cause a system failure. This leads to potential hazards.

Difference between AC Contactors and DC contactors

Several contrasting features between these two types of contactors impact your decision about where to use them. We list these differences here with a description of each.

Structure

The way contactors are built differs between AC and DC. For DC contactors, the contacts are operated by a magnetic coil. This material is made of soft steel or cast iron. They also have fewer poles than AC contactors. They are operated by current-induced magnetic fields around laminated steel sheets.

Principles

Distinct differences in operating principles exist between DC and AC types. DC types use the magnetic field around a coil to manage the contacts. AC types are driven by the magnetic field produced by alternating current.

DC contactors utilize a freewheeling diode to dissipate the inductive load built up over the coils when the supply current is reduced. This feature helps prevent arcing and reduces the fire risk due to excess heat buildup. Depending on the contactor type, the residual energy can also be used to supply power back to the load.

AC types do not use diodes. Instead, they employ laminated cores and shading coils to prevent heat loss, thereby improving efficiency.

Plating Material

While both DC and AC contactors use silver-based alloys for their contacts, the core plating material is different.

- DC: Iron core material

- AC: Silicone steel to prevent overheating

Operating Frequency

The maximum operating frequency refers to how often the device closes or opens its contacts per hour. The differences between AC and DC are as follows:

- AC: 600 times/hour variable

- DC: 1200 times/hour constant

Electrical Resistance

The coil of an AC contactor has low resistance compared to a DC contactor. However, it produces more heat, so an opening exists to let it escape.

- AC: Low electrical resistance but high heat

- DC: High electrical resistance

The Number of Coils

The number of coils a contactor has will depend on the application. In general, DC contactors have more coils than AC Contactors.

Choosing the Right Contactor for Your Needs

Contactors are versatile components. You can use them for industrial purposes, including protection from overload.

These mechanical switching devices differ from relays since they handle currents above 10 amps. Also, in contrast to relays, they come with built-in safety features such as spring-loaded contacts and arc suppression.

Choosing the right contactor for your needs can prove challenging. To make it easier, start with the load ratings. Inductive load ratings refer to motors and transformers. Resistive ratings are primarily for lighting control applications. The most common coil voltages are:

- 12V

- 24V

- 28V

- 400V

Another point to consider when choosing the right contactor is durability. How long your contactors last in a circuit without mechanical breakdown largely depends on the manufacturer, so choosing one you can trust is best.

Contactor Applications

It’s possible to use contactors in various applications. You can find them in:

- Air Conditioning units

- Heat pumps

- Commercial lighting

- Industrial buildings

- Ventilation systems

Electrical engineers often use contactors for large industrial buildings to provide a means of central electrical control. There are also contactors to manage lighting within the same structure.

Another application is the remote switching of electric devices – including HVAC units, motors, and pumps– in series within large industrial facilities. Their compact design and long life make these quiet devices ideal for commercial environments.

Contactors are vital in heavy industrial applications to guard against power fluctuations. They also eliminate harmful harmonics in the power line and protect equipment from damage.

Contactors are designed to be used in buildings with large HVAC systems typically operated year-round. And unlike relays, they are ideal for multiple power-switching applications.

Conclusion

Knowing the differences between AC and DC contactors will help you choose the right one. You must also find the design features and options suitable for your needs.

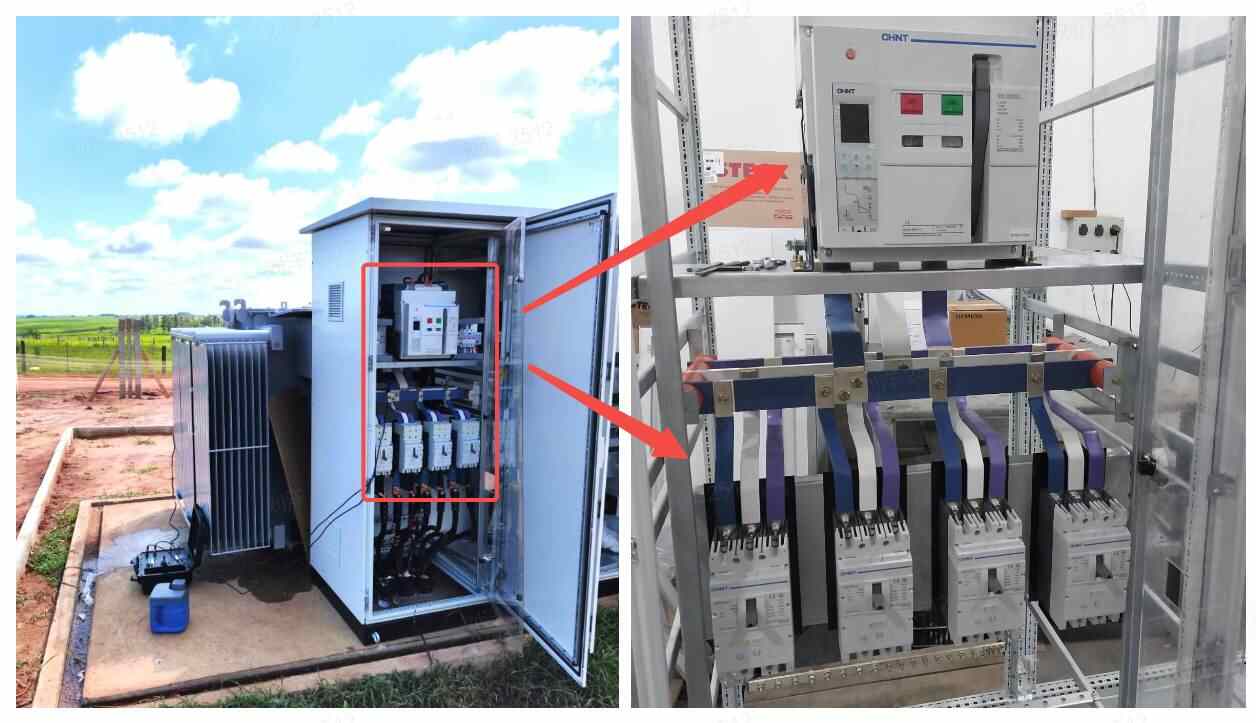

Choosing the right manufacturer also makes a difference. Chint Global is one of the most trusted names in the industry. We manufacture our products using high-quality materials, ensuring long life while reducing maintenance costs.

Chint Global offers a wide selection of modular contactors suitable for commercial, residential, and industrial use.

Whichever type you choose, Chint Global has the right solution for your specific design requirements. Find out more by visiting our product page.

FAQ about AC and DC Contactor

Which type of contactor is more durable, AC or DC?

Are there any safety considerations to keep in mind when using AC or DC contactors?

How do I choose between an AC and a DC contactor?