Table of Contents |

The oil-filled distribution transformer business in the United States is quickly expanding due to the government’s regulations requiring the repair of old grid infrastructure. The U.S. Oil Filled Distribution Transformer Industry is predicted to grow by over 4% between 2021 and 2027.

With such an enormous increase in popularity, it is more important than ever for people to know how to maintain their equipment. Why is maintenance necessary, you ask? Power transformer maintenance not only keeps their internal and external components running but also maximizes their efficiency and lifespan. Additionally, you could operate it safely at any time without it bailing on you at the last minute.

So, to increase awareness regarding oil-immersed transformer maintenance, we have composed this post as a guide to oil-filled transformer maintenance. Let’s get started, shall we?

What Is an Oil-Filled Transformer?

Also known as liquid type or oil-immersed transformers, oil-filled transformers are the most common form of transformers. These power transformers are housed in a welded steel oil tank, such that their coils are submerged in mineral oil.

The oil in oil-immersed transformers serves as a cooling agent, allowing the machine’s heat to be kept under control. When an oil-immersed transformer is in use, the heat generated by the coil and iron core is first transferred to the insulating oil, then to the cooling medium.

Routine Maintenance of Oil-Filled Transformers

Routine transformer maintenance isn’t a one-time thing. It would be best if you drafted individual daily, weekly, monthly, and yearly maintenance strategies. Additionally, you will have to specify different transformer maintenance elements for each period. Here is a guide on how to schedule your power transformer maintenance:

Daily

Day-to-day transformer maintenance routines include oil and temperature checks. You should ensure the ambient, winding, and oil temperatures are within the typical range. Moreover, you should check whether the oil level gauge adapts to temperature changes. If your oil-filled transformer doesn’t accomplish one of these things, it’s time to replace the indicator.

Additionally, you will have to compare the load voltage and current to the rated statistics as part of your daily power transformer maintenance routine. Pro tip: you can avoid electrical failure by keeping your overcurrent, differential, and ground voltage relay in good working order.

It is unlikely for oil-filled transformers to make a lot of noise, but if yours does, you need to figure out what’s causing it. Most of the time, there is an issue with the transformer core, cooling system, and coils.

Weekly and Monthly

You need to check several transformer components on a weekly or monthly basis. These include checking the oil’s dielectric strength, inspecting your cable box, cleaning your transformer’s auxiliary circuits, etc.

Here is a list of things you should include in your weekly transformer maintenance schedule:

- Determining the oil level: examine the oil level indicator and compare it to the oil temperature.

- Visually inspecting the transformer’s outside: look for any deterioration or chipped paint.

- Ensuring that the gasket joints and radiators are secure: check to see if there is no evidence of oil leakage.

- Ensuring appropriate sealing: Inspect any pressure relief device vent fitted on the cap.

- Check for signs of proper operation on the pressure release device.

Yearly

Your annual transformer maintenance schedule will include all the previous tasks mentioned in the daily and weekly schedules. Plus, it will include less frequent checks and complex tasks.

The tasks to include in your yearly oil-immersed transformer maintenance plan include:

- Inspect the temperature indicators and off-circuit selector, and replace them if necessary.

- Check the weatherproof seals on the marshaling boxes.

- Measuring the insulation resistance of the transformer’s protection relays.

- Examining the resistance of the fan or oil pump motors.

- Assuring that there are no leaks around the pressure relief tank.

Potential Problems with Oil-Filled Transformers

Reality check: you will encounter several issues during your routine transformer maintenance. Yep, oil-filled transformers have many common issues. Understanding these and how they appear might assist you in identifying any warning indications of increased risk of complications.

Here are some common warning signs that your transformer needs to be repaired or replaced:

Presence of Sludge

Chemical reactions such as polymerization and breakdown produce particulates that build within the winding structure, resulting in sludge formation. Oil oxidation and degradation can also be caused by moisture and humidity.

Signs of Aging

Signs of aging, such as degraded insulation, might provide insight into your machine’s remaining useful life. Components will gradually wear out and require more maintenance as they age, so it’s time to consider replacing your system.

Oil Leaks

Leaks from gaskets, cooling radiators/fins, tanks, gaskets, and other transformer parts can cause oil leaks. You can repair occasional leaks, but upgrading the system is the only option in case of frequent oil leaks.

Benefits of Preventive Maintenance for Oil-Filled Transformers

Transformers benefit from preventive maintenance in the same way that any other industrial machine does. Pairing preventive maintenance tactics with another approach, such as predictive maintenance, can improve the efficiency of your upkeep. Naturally, having a well-thought-out repair strategy has numerous benefits:

Increased Equipment Life Expectancy

Proper and timely maintenance will increase your transformer’s estimated useful life. As a result, you may avoid replacing expensive parts regularly, and you can acquire a machine that lasts as long as possible. A generator step-up (GSU) transformer, for example, can live up to 25 years if properly maintained.

Enhanced Worker Safety

A well-maintained transformer is less likely to cause hazardous occurrences such as explosions or electrical failures. Even though relay mechanisms are in place to prevent these situations, there’s no harm in taking extra precautions.

Improved Time Management

A fine-tuned transformer operates more effectively and breaks down less frequently, allowing you to avoid the costs of unscheduled downtime. Furthermore, by arranging your upkeep schedule, your staff will be able to do less complex maintenance chores more rapidly, increasing their overall productivity.

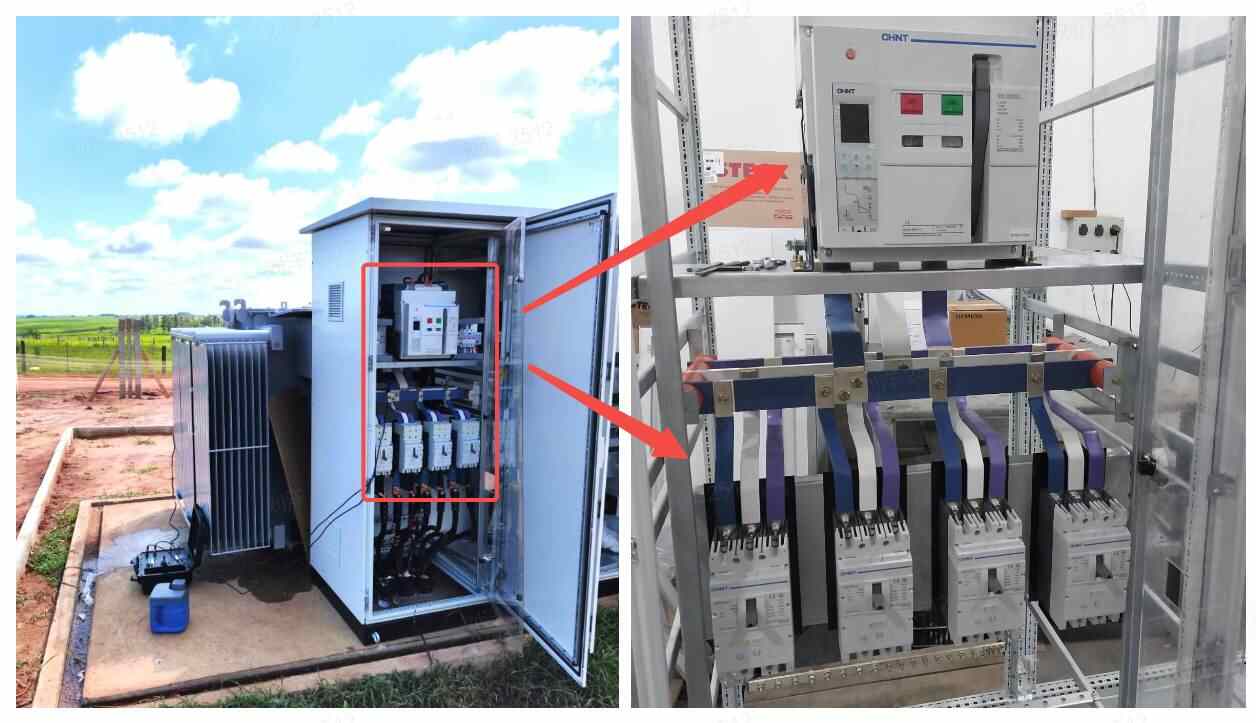

CHINT Oil-Immersed Transformers

While regular maintenance is mandatory, you can decrease your workload significantly by investing in a good-quality oil-immersed transformer. We vouch for the CHINT oil-filled transformers as they provide the safest, most reliable, and most efficient power delivery.

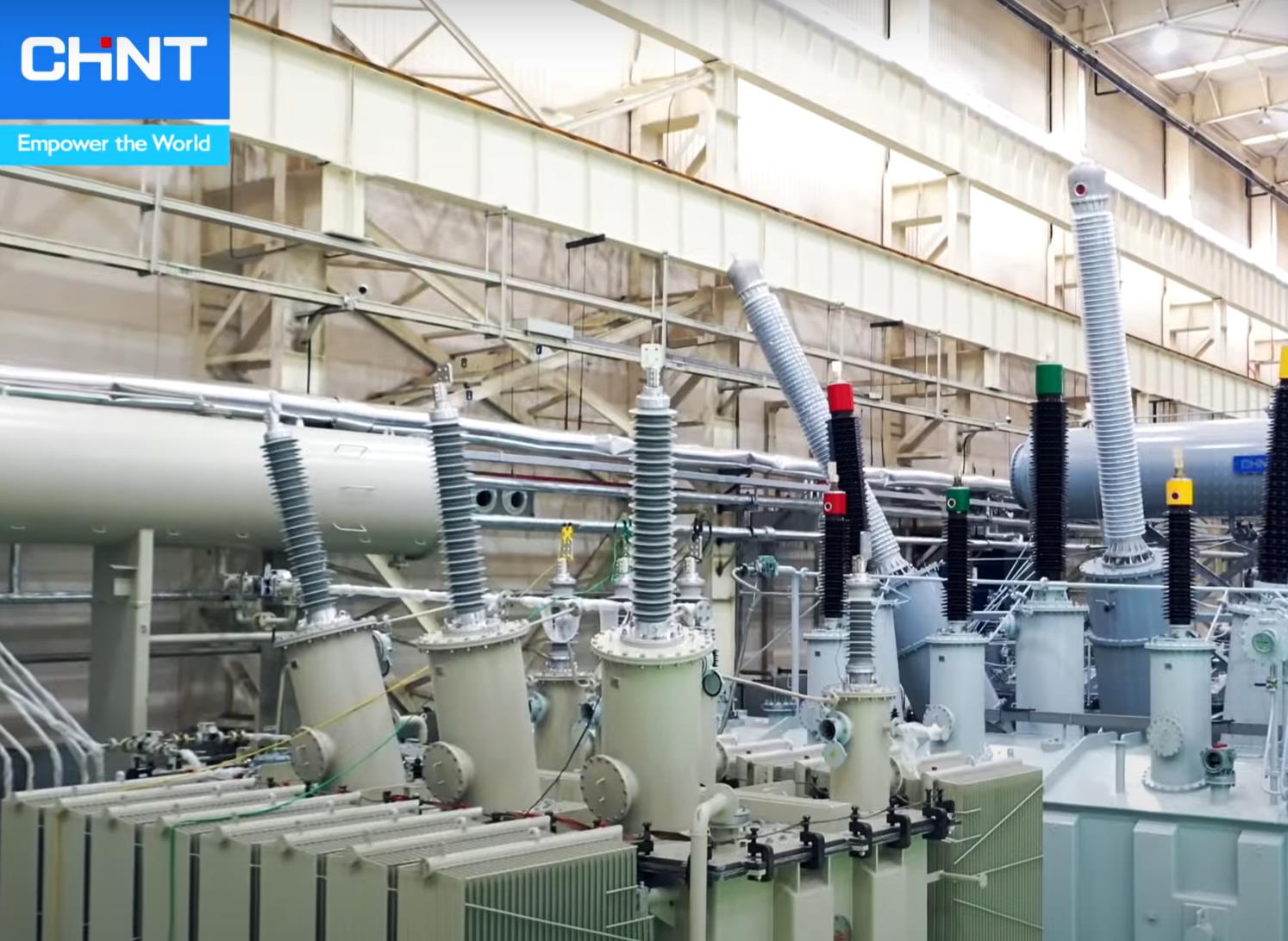

110kV Power Transformer

The CHINT 110kV Power Transformer is ideal for power plants, substations and large-scale industrial applications.

Features:

- Highly secure and reliable

- Efficient in reducing network loss and operating costs

- Excellent insulation strength

- Lightweight design

- Fast delivery

220kV Power Transformer

The CHINT 220Kv Power Transformer is ideal for power plants, power stations, and large-scale industrial applications.

Features:

- High operational security and dependability

- Cost-effective

- Great insulation capabilities

- Compact and lightweight

- Low noise generation

- Fast delivery

The Bottom Line

When buying an oil-filled transformer, you should consider maintenance essential to keeping it in good working condition. When it comes to maintenance, getting ahead of equipment issues can allow you to solve the problem sooner.

That said, you can lessen the tasks on your transformer maintenance schedule by investing in the CHINT oil-immersed transformers. Not only do we have a large capacity, but we will also help you save substantial energy, prevent power loss, save energy sources, and reduce operational costs.