Table of Contents |

|

Solar energy is one of the fastest-growing energy sources. The photo-voltaic (PV) technology is gradually becoming an essential source for electricity generation. Due to environmental concerns and depleting fossil fuel reserves, the technology stands to gain attention worldwide.

Many countries aim towards solar PV module as a means of cheap, clean, and reliable power for utility, industry, and individual purposes. In this article, we’ll discuss what PV module is and why it’s used, the six major parts of PV modules, and the types of PV modules.

What Is PV Module and Why It Is Used?

Photo voltaic modules are a packaged or unpackaged assembly of cells, substrates, and conductors for converting photon energy into direct current electrical power.

The term “module” describes a die-cut piece of solar cell material that can be electrically interconnected to other modules as part of a photo-voltaic system. Modules typically have a front surface that faces the sun and a back surface with electrical contacts from which the included cells are wired.

Inverters make it possible to use these DC currents in appliances, pumps, lighting systems, and indoor or outdoor household panels. In addition, some newer inverters help you monitor your PV system’s status via an Internet connection.

Depending on what you’re planning to power with PV energy, you may need a third-party inverter. Here are reasons why PV is very useful:

- PV is clean energy.

- PV is cost-effective when you know how to shop for solar panel prices.

- It’s prudent to invest in renewable energy sources since fossil fuels are limited in supply and contribute to global warming when burnt.

- You can save money on electricity bills by using solar energy.

- You can use PV panels to recharge your batteries which are critical for powering remote homes and small communities.

- There are different PV modules available, based on whether it’s made for utility-scale or rooftop use.

What Are the Major Parts of a PV Module?

PV modules are made up of various components. However, there are six major components that you should know. Here are the six components.

Solar Photovoltaic Cells

Solar photovoltaic cells are the main components of a PV module. There’s a thin layer, just a few micrometers thick, of a semiconductor material such as silicon on which photons are striking the surface to liberate electrons that can be collected at electrodes attached to the top and bottom surfaces. The cells are wired together in series with input and output contacts at the front and back to form a PV module.

Batteries

Batteries can be added onto PV modules for storing electrical energy when sunlight is present, but power demand is low. Hence, batteries are not required when connecting your PV systems directly to utility companies during the daytime. However, batteries should be used for direct connection to utility companies at night or if it’s a cloudy day.

Extruded Aluminum Frame

The aluminum frame is needed to set the solar cells in place and help you connect them electrically so they can function as a PV module. The frames are made from metal extrusions that have been anodized or coated with silicone rubber to protect from moisture and air exposure due to their positioning on the rooftop panels of homes and other buildings.

Solar Inverters

Inverter helps convert direct current (DC) produced by a PV system into AC compatible with the electrical grid. It increases energy losses during this conversion process but provides more efficient power at the point of use. The inverter should be sized according to your system’s size and the number of modules.

Back-Sheet

The back-sheet is a fire-resistant, waterproof material added to the rear surface of PV modules to protect them from moisture and air exposure. Most back sheets are made using polyvinyl fluoride (PVF), although ethylene vinyl acetate (EVA) and copolymer back sheets also exist. Lastly, you need special tools such as solar panel mounting brackets for attaching your PV module on your rooftop or pole mounts for ground-mounted systems.

Junction Box - Diodes and Connectors

A junction box is part of a photo-voltaic system’s design where the solar panel’s positive and negative terminals connect without a direct electrical connection to the PV system. This prevents power from flowing back into your inverter when no sunlight is present.

In addition, it allows you to add or remove panels from your system in smaller increments rather than having to replace an entire string of modules at once when you need additional or fewer watts from your photo-voltaic array.

What Are the Types of PV Module?

Three types of PV modules are available depending on the semiconductor material used to make the PV cells. Here are the three types.

Monocrystalline

Monocrystalline or single-crystal silicon is made from a single piece of silicon crystal cut from a large ingot cast in an electric furnace under very high heat conditions. The resulting silicon wafer is 99% pure, which means its conversion efficiency rate can be as high as 25%. Its price is higher than other types but can last up to 40 years if handled correctly. Monocrystalline PV modules are more expensive than different types, but they have the highest efficiency.

Polycrystalline

Polycrystalline or multi-crystalline silicon is made from molten silicon cast in a mold under high pressure. The resulting wafers are formed with multiple crystals, which reduces their conversion efficiency rate to 13%. They’re more affordable than monocrystalline PV modules, but they have a shorter lifespan of about 20 years, with degradation occurring earlier.

Thin-Film

Thin-film solar cells are made using semiconductor materials such as amorphous silicon, cadmium telluride, and copper indium gallium selenide. They’re the most economical type of PV module but have a maximum conversion efficiency rate of around 8%.

However, researchers are finding ways to raise their efficiency rates. These include using concentrated photo-voltaic (CPV) systems where lenses or mirrors concentrate sunlight on tiny sub-surface solar cells only 1 micrometer thick.

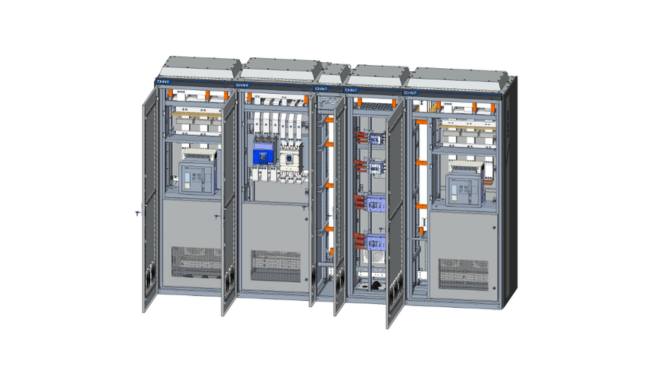

Chint PV Module Products

Chint Solar is a PV module manufacturer founded in 1984 in Zhejiang, China, with international headquarters in Singapore. In 2015, it launched the new EV series of glass-glass PV modules that last longer and capture more sunlight to boost its power generation efficiency rates from 14% to 16%.

These products use a lightweight design where the cell’s silver grid is printed directly on a light-transmitting back sheet. They’re also equipped with electricity disconnect switches that allow users to isolate faulty cells or modules without replacing the entire unit.

Chint Solar has about 3 GW of solar capacity installed by customers worldwide. It offers six different types of PV modules, including monocrystalline, polycrystalline, and thin-film types for residential rooftops, commercial buildings, and utility-scale power plants.

Conclusion

PV modules are key components of a photo-voltaic system where sunlight is converted into direct current (DC) electricity. It consists of silicon cells absorbing sunlight and producing the DC power to charge your battery bank. If you are interested in PV modules, Chint Solar has the best products and components.