Table of Contents |

Prefabricated substations are quickly becoming an essential part of the electrical system. These substations allow for the raising and lowering of voltages and can aid in power distribution to consumer areas. Read on to learn more about prefabricated substations and how they can be helpful for you.

What is a Prefabricated Substation?

Substations are located within a power system and allow voltage to be stepped up or down, depending on whether it’s traveling to consumers or other stations. Substations are either transmission or distribution substations. Transmission substations step up the voltage to enter the grid, while distribution substations lower the voltage for consumer use. Prefabricated substations function as distribution substations but can also set up voltages when needed.

A prefabricated substation is similar to a substation and is usually located in cities and urban areas. You may find these substations along the side of the road, near businesses, in neighborhoods or near parks. They are often built to look like houses. With a prefabricated station, the manufacturer constructs most of the components. Once received, you will assemble it following manufacturer instructions.

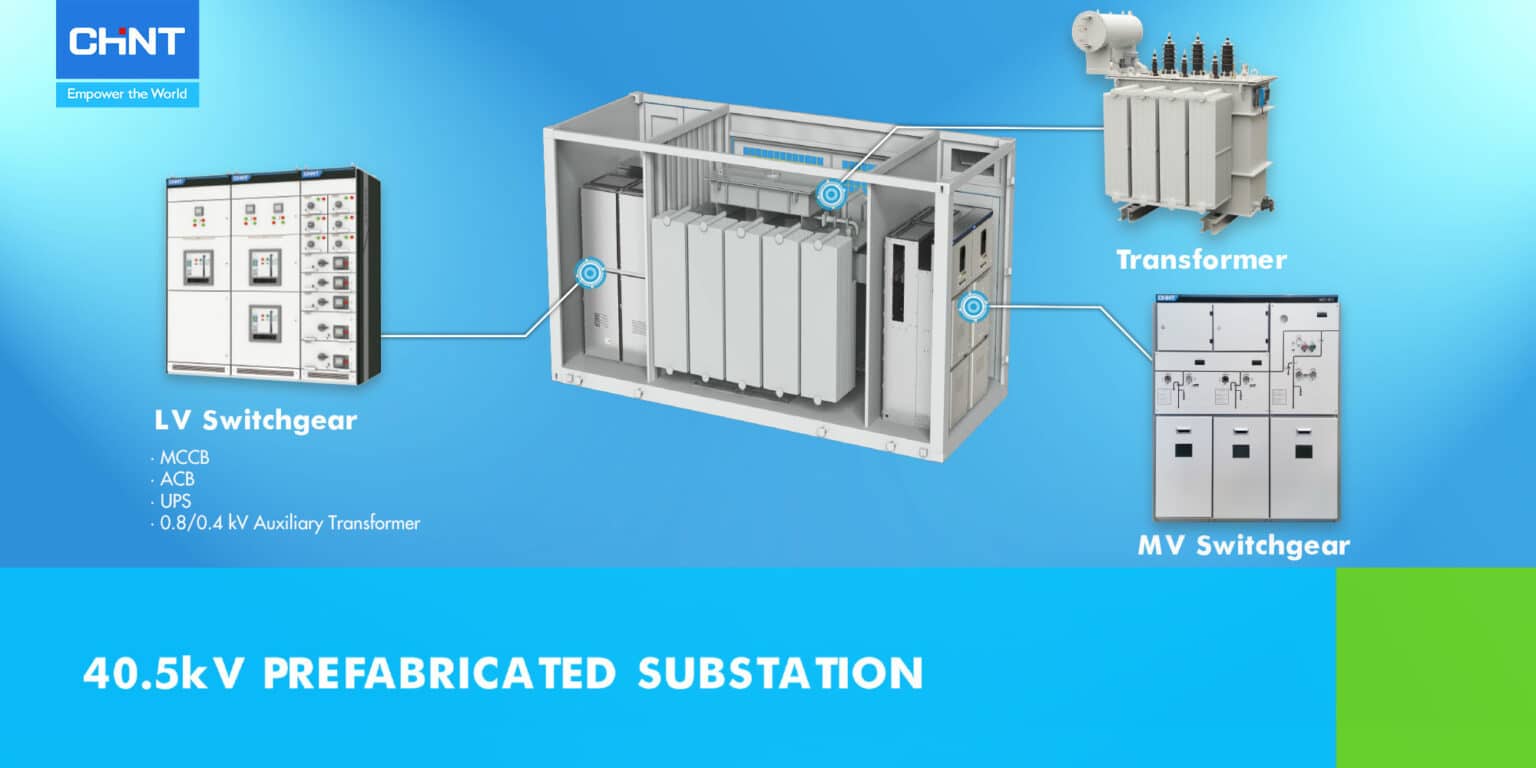

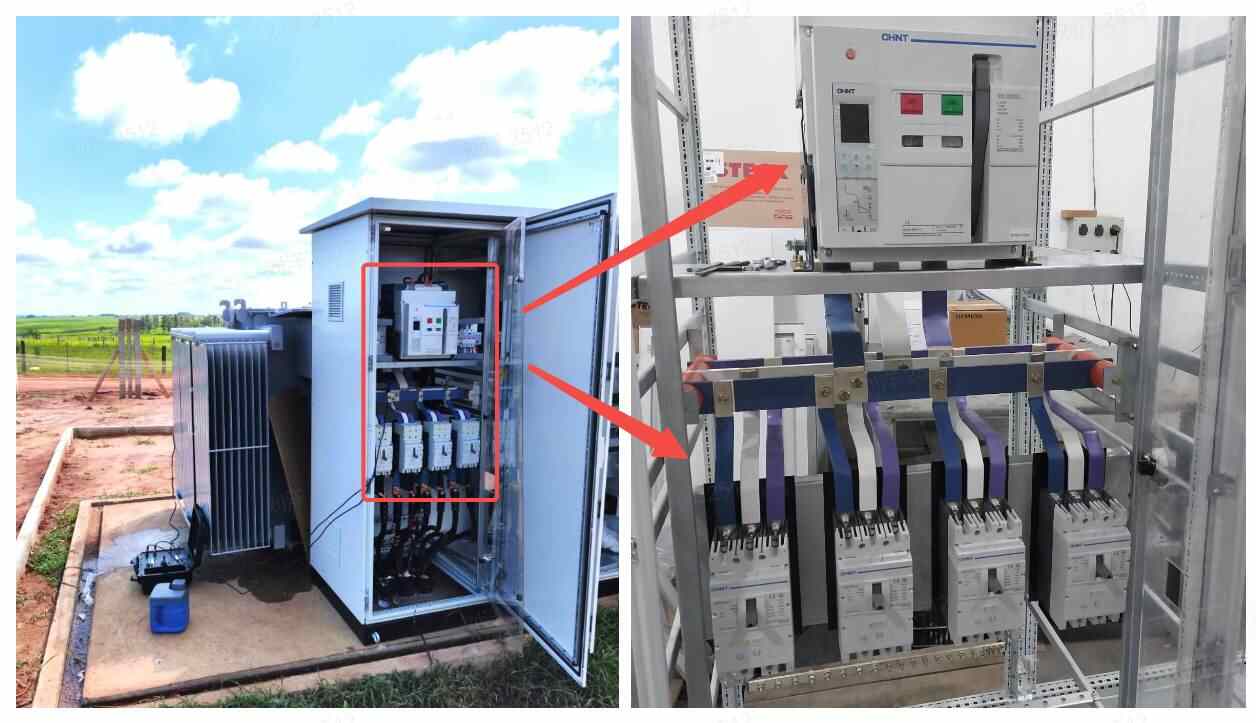

You will find three main components housed inside the substation – switchgear for higher voltages, distribution systems for lower voltages and transformers. Transformers receive energy at one voltage and then step the voltage up or down before distributing it. High-voltage switchgear manages higher voltages while a distribution system manages the distribution of lower voltages.

There are many advantages of a prefabricated substation. It is smaller, and because most of it is already manufactured, it’s quick and easy to assemble. You’ll only need a concrete slab before assembling your substation. It is easy to make a substation fit in with its surroundings, allowing you to keep an area’s aesthetics. Finally, the maintenance costs are lower.

Types of Prefabricated Substation

There are two main types of prefabricated substations – an integrated substation, also called a pad-mount transformer, and a combined substation, also known as a compact transformer. Each of these serves slightly different purposes, and you’ll choose the best based on your situation’s needs.

In an integrated substation, the transformer makes up the main body of the structure. It contains load switches and fuses inside its enclosure. The enclosure is sealed and insulated and requires little to no maintenance. You will need to prepare a pad before building the station. It tends to be smaller than other substations.

Integrated substations are further divided into two sections, a front and back. The front part contains the high- and low-voltage terminals. It also includes bushing and pressuring regulating load switches in the high-voltage terminal and oil filling valve and temperature gauge, nameplate, and copper grounding bar in the low-voltage terminal. The radiator and transformer tank are located in the back.

A compact substation has the same components – a transformer, a high-voltage switchgear, and a low-voltage distribution system. It differs from an integrated substation because each component has its own “room” within the substation. They are in a mu formation, which is more convenient, or a pin formation, which is more compact.

Compact substations typically apply the pin formation when several transformers are in use. One of the biggest advantages of a compact substation is that you can rearrange the components to fit different situations.

Functions of Prefabricated Substation

In any electricity distribution system, it is necessary to step up or step down the voltage at certain points. Electricity passes through substations to change voltages. While substations typically manage smaller voltages, with transformers stepping down the voltages, prefabricated substations can handle larger voltages and perform both step-ups and step-downs.

Prefabricated substations transform power from AC to DC and back to AC. It allows for higher currents when power stations and consumers are far apart from one another. Many can transform from AC to DC for high voltages, combating power loss.

These substations can save energy, which is good for the environment and consumers. Most prefabricated substations are high-voltage stations and can manage currents of medium voltage or lower levels of high voltage.

For example, at Chint Global we offer a factory-manufactured compact substation. It can manage high voltages of 3.6-24kV and low voltages of 0.4kV. The substation is lightweight and appropriate for use in urban and rural areas.

Prefabricated substations are easy to ship and assemble. When installing a substation, choose a safe spot for the concrete pad. Avoid any nearby flammable materials and areas where explosions may occur. Set up the substation on the windward side of the main building. Finally, avoid areas with lots of people, and keep other factors like weather, the environment and wildlife in mind.

Applications of Prefabricated Substation

One of the biggest advantages of prefabricated substations is that they are useful in many different situations and setups. These substations are helpful in rural and urban settings. It’s also easy to manufacture to your exact specifications, which is helpful if you have a unique setup that may not work with a traditional substation.

Prefab substations are suitable for use in industrial, commercial and residential locations. They are suitable for factories, mines, construction zones and more. Rural neighborhoods and businesses may also find prefab substations suit their needs better than conventional substations.

Construction sites may opt for a prefabricated station as they can easily move between sites. Some industries with a substation may purchase a prefabricated system as a backup. Because prefabricated stations are so easy to take down and reassemble, they are often used as backup power when a conventional substation is undergoing maintenance and repairs.

Conclusion

Prefabricated substations can fit a variety of situations. They can also help save space and energy. Chint Global offers prefabricated substations along with other electrical equipment to help you get the perfect setup for your needs. Contact us today and one of our representatives will help you figure out what system will work best for you.

FAQ about Prefabricated Substation

Why choose prefabricated substations over traditional ones?