Table of Contents |

Intelligent manufacturing is becoming a worldwide trend. Intelligent manufacturing, or smart manufacturing, is the key to tackling changing customer dynamics and the need to remain competitive with enhanced efficiency and reduced waste. Manufacturers and suppliers are transitioning to smart manufacturing to optimize production with advanced robotics, automation, and sensors. In this guide, we will uncover everything about intelligent manufacturing and present its practical use with case studies.

What is Intelligent Manufacturing and Its Features?

Intelligent manufacturing is defined as smart manufacturing that utilizes real-time data analysis, artificial intelligence, machine learning, and the internet of things (IoT) to have optimized manufacturing with robotics automation. In simple words, it is the combined intelligence of people, machines, and processes to drive whole manufacturing operations.

The smart manufacturing system can help to adapt to different production requirements and changing environments. It provides real-time data and a 360° view of all operations regarding the supply chain, manufacturing processes, product testing, etc.

The main purpose of intelligent manufacturing is to optimize manufacturing resources/processes, reduce waste, and improve business value, all while fulfilling customer demands and quality needs. This way, manufacturers have a proactive approach rather than a reactive one with greater flexibility and adaptability.

The key features of intelligent manufacturing are as follows:

Intelligent

The whole manufacturing process becomes intelligent with artificial intelligence, machine learning, data analytics, IoT, and much more. For instance, the use of IoT sensors with cloud computing helps to interlink machines and connect them with workers. The sensors are able to provide information on various aspects of the machines, such as temperature, inventory levels, etc. Afterwards, data analytics leads to predictive maintenance, process optimization, and quality control.

Efficient

Another key feature of intelligent manufacturing is enhanced efficiency. Real-time data analytics and 360° visibility of processes help to optimize resource utilization with lower material waste. For instance, predictive maintenance can lower the chances of machine breakdowns and prolonged downtimes. Similarly, smart monitoring of inventory levels leads to effective inventory management instead of overstocking.

Automated

Automation is another key aspect of intelligent manufacturing. With automated manufacturing processes, you can reduce manual labor and increase accuracy. Beyond just robotic automation and smart machinery, today’s robotic solutions are integrated with AI and ML to handle advanced tasks. For instance, they can detect manufacturing defects to enhance product quality and reduce flaws.

Intelligent Manufacturing: An Integral Part of Production in Many Companies

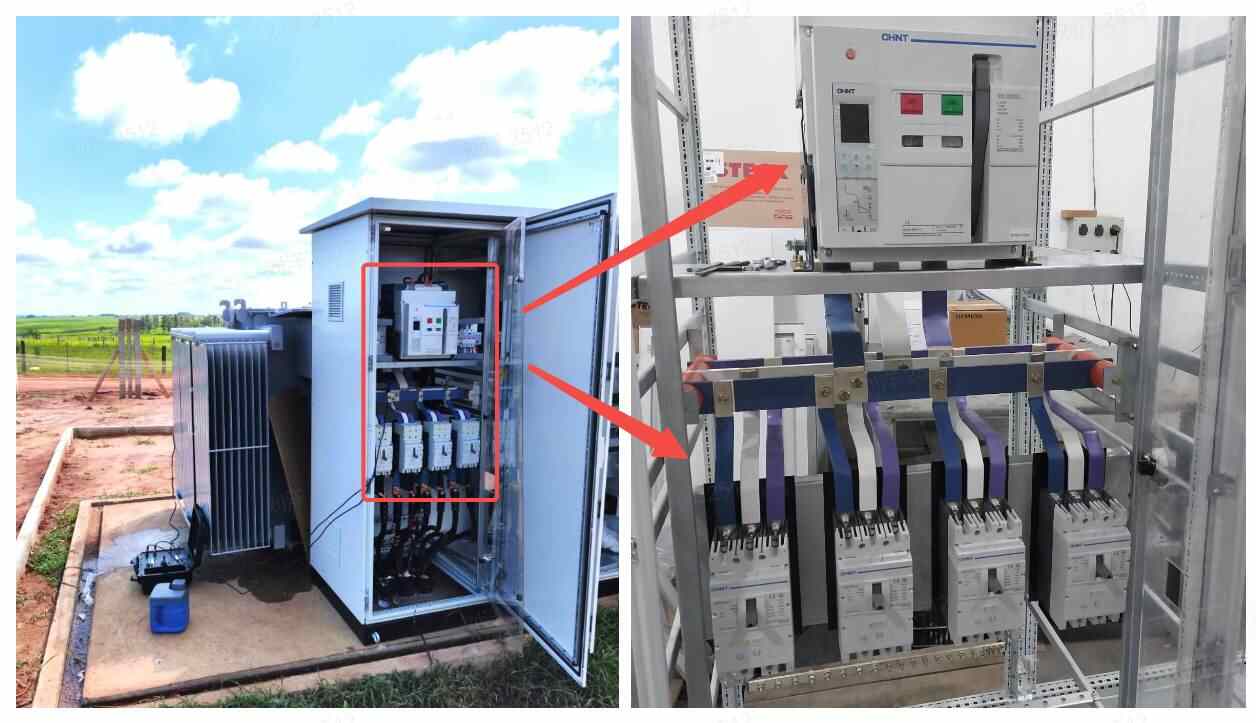

Many companies have incorporated intelligent manufacturing into their production. As a leading smart energy solutions provider, CHINT is also one of those companies leveraging intelligent manufacturing. Below is a deeper look at how CHINT is leveraging automated production lines and setting up the trend of “Industry 4.0” in the low-voltage electrical industry:

CHINT Automatic Component Production Line

CHINT set up the Digital Workshop of the Component Manufacturing Department back in 2017, which is one of the six digital workshops of the company’s Wenzhou future factory. The workshop has an integrated automatic production line for welding and punching, which is the first of its kind for manufacturing miniature circuit breakers (MCB). On top of that, it is the only fully automated production line in the low-voltage domestic electrical industry.

The production capacity is 800,000 pieces per day (highest). The automated production line does not require any human intervention. From material feeding and component input to component output, the company has been able to:

- Save over 1,100 workers

- Increase more than 90% in per capita hourly production capacity

- Reduce more than 57.18% in operation and production costs

- Reduce online product defect rate by over 90%

Overall, the CHINT automatic component production line is at the forefront internationally and has even managed to obtain 31 patents, which includes 14 invention patents.

CHINT Digital Workshop for MCB

CHINT has 14 fully automated production lines for NXB-63 MCB manufacturing. The company has itself designed and developed all the main software systems and equipment for this workshop.

The digital workshop for MCB is one of the first “future factories” in Zhejiang Province and integrates intelligent logistics and warehouse systems (WMS), manufacturing execution systems (MES), energy management systems (EMS), big data monitoring platforms, and much more. This fully automated digital workshop for MCB intelligent manufacturing has helped the company:

- Reduce the employees from 87 to 10 (working in two shifts), saving a total of 1000+ people

- Reduce the operating costs by over 40%

- Increase the per capita efficiency by sixfold

- Reduce 60% defect rates

Overall, the CHINT digital workshop for MCA is dominating the worldwide low-voltage electrical industry in terms of digitization, automation, production efficiency, and product quality.

Conclusion

Intelligent manufacturing is the key “Industry 4.0” (fourth industrial revolution) component. The smart use of AI, machine learning, IoT, and the cloud are driving the much-needed smart manufacturing that manufacturers need today. And that’s just the beginning of the intelligence and automation we are going to witness in the manufacturing processes over the coming years. Henceforth, it’s time for manufacturers and suppliers to embrace smart manufacturing, just like CHINT, and automate production with optimized use of resources and workforce.