Table of Contents |

In the past few years, before the arc fault detection devices were widely embraced in the electrical installations, many reported and unreported fire accidents resulted from the electricity. With the current wide usage of the arc default detection devices, the reported cases of electrical fires have significantly reduced.

This has reduced the number of losses businesses, and domestic families were going through when their properties and business were coming down in unexpected fires. However, the use of the AFFD does not necessarily mean that there can be no electric fires.

What is arc fault detection?

Before getting to the faulty arc detection, you must understand the basic terms, such as the arcs. The arcs are visible when the electric current tries to pass through a non-conductor material such as the air.

The current ionizes the air particles, which leads causes a rise in temperature, hot enough to cause an electric fire. Arcs are formed in the installed electrical wiring when the current finds a gap between conductors. The gap can result from a worn-out electrical wire, a loose connection of the wires, and a damaged insulator.

Fault detection is finding those defaults that can cause these electrical arcs, leading to fires. To prevent arc faults, the electrician installs arc fault detection devices during the electrical wiring, which in common knowledge are known as circuit breakers.

As the name suggests, they break the current flow and cut down the current. They detect any defaults or the current overload and act as a switch to cut down the current.

How does an arc fault detector work?

You cannot trust the circuit breakers for your protection against the arcs, and this is because they cannot detect the electrical arcs that happen suddenly. They can only protect you from the short circuits and current overloads that can happen.

The arc faults can strain the cables, connections, plugs, and adapters, wearing out their insulators and leaving the wires loose. It leaves weak points in your electrical system, exposing you to electrical fires. That is why you need a full installation of the arc fault detectors in your buildings. Using certified plugs and adapters cannot be an assurance of your safety.

The detectors are manufactured to detect the dangerous arcs in the electrical system and cut the flow of the currents to the affected side. The arc fault detectors are made with microprocessor technology (special algorithms), which can analyze the current flow and detect strange signatures that cause electric fires.

In the case of the fault arcs, the AFDD trips off, cutting the current flow to prevent the arcs from reaching the faulty points. The arc fault detectors work better than the conventional circuit devices. The arc fault detector does the following:

- The added protection from the RCD does not exceed 30 mA

- It has a fault protection mechanism that automatically cuts the current flow to the direction experiencing arcs.

- It offers basic electrical protection by having an insulator layer covering it to prevent users from coming into direct contact with the electricity.

What are the 2 types of arc fault detectors?

There are two types of arc fault detectors. They are:

Parallel arc

the parallel arc fault only occurs when the live wire contacts a neutral conductor; this includes the earth’s surface. When such a fault occurs, any residual current device installed in the AFDD will cut the supply of current to the affected area of the circuit.

Series arc

it happens as a result of the break of the conductor. This is more likely when the wire is cut or due to a loose terminal of a socket.

CHINT arc fault detection devices

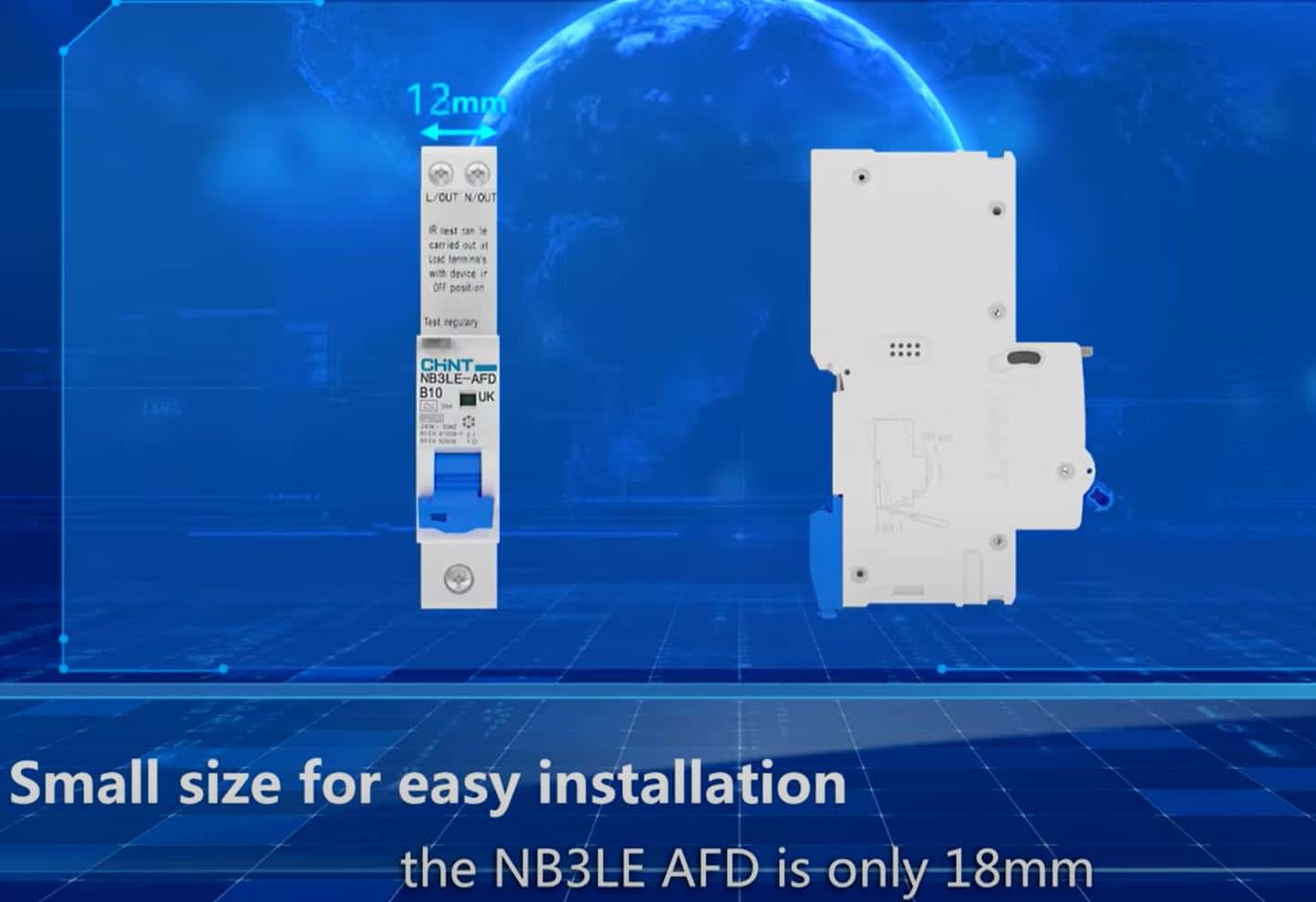

1. NB3LE-AFD

NB3LE-AFD is one of the circuit breakers used to cut the current flow when you experience arcs. It has the power to break the circuit and is also used as an arc fault detector. It can only be used in the circuits that carry the currency of 50 Hz and the 240V of the alternative currency (AC).

The current carried in the circuit should be equal to or below 35A. It is normally used in the protection of the overloads, when the live wire and the neuter wire come into contact, causing a short circuit, in case there is a leakage of the electricity, there is a fault in the circuit, and when you want to switch off the power to your house or building in the normal circumstance.

The selection available in the markets

In the RCD type; there is only one RCD in the market, the type A. Type A is made in such a way that it can cut the flow of the power when there is a successive high electric power wave, ranging waves of the electricity no matter whether they are raising very fast or slowly.

Tripping curve

- B curve protects in times of overload and humping electric power.

- C curve ranges between 5 to 10 inches. It provides protection against overload and humping waves of electricity. In addition, protection against electricity that arises from inductance with low rushing in current.

2. NB4LE-AFD

NB4LE-AFD is used with the circuit that carries the electric power of 50 Hz, the voltage of 230 to 240 AC. It should carry the currency of at most 32A. It is usually used in:

- Overload

- Arc fault detection

- You can use it to switch off the electricity infrequently

- Leakage protection

Types available in market

- RCD type

- Tripping curve; B curve, C curve, BK curve, and CK curve.

Nearly all countries in the world have embraced arc fault detectors. To be granted the Electrical Installation Certificate, your electrical installation must have the arc fault detect devices.

Also, to play safe with either your business or premises, ensure that your electrical installation by a certified professional do the follow-up to ensure that the arc fault detectors are well installed. In case there is an arc fault, take precautions. Seek help from an electrician near you as soon as possible.