Table of Contents

The molded case circuit breaker (MCCB) is but one of many circuit breaker varieties. These devices take center stage in power distribution and fault protection thanks to their distinct benefits. They’re so successful that the market will reach almost $13 billion by 2030.

These devices might not look too distinct from standard breakers to the uninformed. However, their durability and high-end performance specifications put them in a completely different class. Here’s a deep dive into how MCCBs work and how Chint Global innovates with this technology.

Understanding the Working Principle of MCCB

All circuit breakers operate on the same fundamental principle. When an electrical fault occurs, they interrupt — or break — the circuit. By opening circuits at high speeds, breakers prevent damage, reduce fire hazards, and increase the longevity of equipment.

Molded case circuit breakers are slightly different. Unlike their traditional counterparts, they can supply heavy electrical loads with precision.

MCCBs accomplish their jobs with the help of many high-end components. A few highlights include:

- The trip unit. This is the “brain” of the breaker. It monitors current flow to tell the device when to break the circuit.

- The operating apparatus. This physical switch opens the circuit after receiving a signal from the trip unit. An operator can also toggle it by hand or remote control.

- The molded case. This rugged, nonconductive outer housing holds everything together.

What are the Benefits of MCCB?

MCCBs set themselves apart from conventional circuit breakers in many ways. One big advantage is their enhanced dependability. These devices protect equipment and people against overcurrent, short circuits, and ground faults. What’s more, they require minimal maintenance and almost zero oversight.

These breakers handle faults and high inrush currents with ease. As such, they can operate nonstop under extremely challenging conditions. These combined features make molded breakers the only sensible choice for industrial applications.

The high current ratings on molded breakers come with an added bonus. They can act as primary surge protective devices in distribution panels. Many Chint Global models also feature arc extinguishers. These elements divert current arcs to maximize the useful lifetime of the breaker.

Versatility is another major benefit of molded case breakers. They protect everything from motors and generators to welding machines and capacitor banks.

It’s worth noting that these devices aren’t only for heavy loads. They also perform flawlessly in low-power applications thanks to their precision and sensitivity.

As you’ll notice when browsing the Chint Global catalog, our MCCBs are highly customizable. We can provide a variety of devices to meet your specific application requirements. Whether you need adjusted trip settings, extra switches, or remote monitoring interfaces, you can depend on Chint MCCBs.

We pay close attention to key engineering details and iterate on every design until we achieve perfection. As a result, our products exemplify safety, reliability, and customizability.

Applications and Use Cases of MCCB

You’ll find MCCBs in a range of diverse industries and settings. Although they typically operate behind the scenes, they play an integral role in keeping job sites running smoothly.

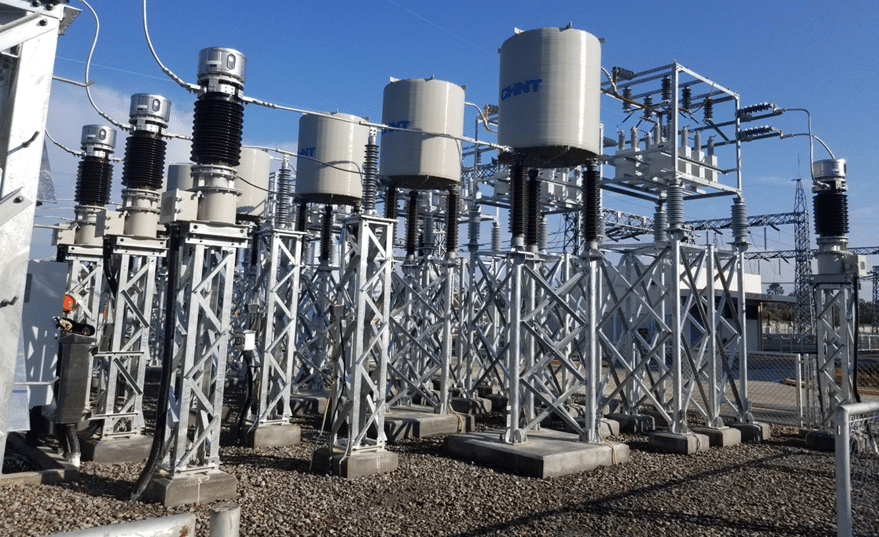

You’ll commonly encounter molded case breakers in industrial plants. Many fabrication lines and factories rely on high-power equipment. The motors, switches, heaters, and relays found in these spaces can draw thousands of amps of current. Reliable protection is vital to keeping workers and assets safe.

MCCBs also improve habitability in commercial spaces. Large retail centers and warehouses may use them to supply HVAC systems or high-voltage lighting.

In the residential sector, MCCBs provide robust protection for electrical panels. They ensure the safety of homes and their occupants in multifamily residences, apartments, and mixed-use-zoned buildings. As more landlords adopt renewables, molded breakers may also play bigger roles in solar energy.

As a rule, you can expect to run into an MCCB or two whenever you distribute power. This includes protecting the distribution board as well as any generators and attached equipment. Whether they’re safeguarding your residents or industrial assets, MCCBs are versatile and dependable.

Safety Features and Protections Offered by MCCBs

Safety is a huge concern when you’re considering current protection hardware. Chint Global’s molded case circuit breakers exceed your expectations with specialized features:

- Thermal overload protection keeps breakers, contact terminals, and wiring from overheating.

- Short circuit protection rapidly cuts off power during short circuits and transient events.

- Ground fault condition protection can disconnect a circuit to prevent shocks or fires.

- Arc diversion stops high currents from degrading motor windings and other sensitive circuits.

- Molded housings can stand up to intense hydraulic pressure without sustaining damage.

Tips for Choosing the Right MCCB

Not every molded circuit breaker is a perfect fit for every job. It’s critical to pick the correct hardware for your needs.

What should go into your decision-making process? Consider these three factors: the electrical load, the installation environment, and the breaker’s specifications.

Calculate the Electrical Load

Be sure your circuit breaker is capable of protecting the load. Always remember that some loads may draw more power under certain circumstances. It’s a good idea to leave yourself room for error.

Evaluate the Entire Installation Environment

The conditions inside wiring runs, breaker panels, and conduits are just some of the things you need to inspect. Molded case breakers must also withstand varied temperatures and humidity levels, especially in large spaces like warehouses. In some cases, they’ll even have to resist vandalism or contaminants.

Check the Breaker Specifications

Finally, remember to match your breaker’s specifications to each job. Review industrial drawings and product pages to learn more about form factors, terminal layouts, and sizes.

You may be interested in this blogpost

Conclusion

MCCBs are a cornerstone of electrical safety and reliability. When selecting breakers for electrical installations, always do your research. Understand the application, and learn the features of your preferred hardware. By doing so, you’ll make a more informed, safer choice.

Chint Global MCCBs redefine safety and performance. Protect your equipment and personnel by visiting us online.

FAQ about Molded Case Circuit Breaker (MCCB)

While both are designed to protect electrical circuits, MCCBs handle higher current capacities and have adjustable trip characteristics. MCBs are typically used in residential settings, whereas MCCBs are often found in industrial or commercial environments.

Apart from overcurrent protection, many MCCBs provide additional safety features like ground-fault interruption, short-circuit protection, and under-voltage release. Some advanced MCCBs can even communicate their status or faults to building management systems.

Yes, MCCBs can work in coordination with other protective devices like fuses or other circuit breakers to achieve selective coordination in complex electrical networks, ensuring minimal disruption during faults.

Recommend Reading

Miniature Circuit Breaker: Working and Application

Table of Contents Miniature circuit breakers are small but mighty safety components that protect circuits from damage. They are crucial to safely and efficiently operate

Residual Current Operated Circuit Breaker (RCBO): Function and Application

Table of Contents In today’s modern world, there’s no lack of sensitive electrical equipment that we rely on throughout our day-to-day life. With costly electrical